Allspec Engineering

For Mining Companies

We help maximise plant productivity by focusing on the rapid delivery of quality fabrication that fits first time.

Allspec Engineering

For Mining Companies

We help maximise plant productivity by focusing on the rapid delivery of quality fabrication that fits first time.

Download Capabilities Statement:

Download Capabilities Statement:

Our entire fabrication process is designed to provide a competitive advantage for our clients.

Our vertically integrated supply chain ensures complete control and transparency throughout the entire project, from detailing through to site delivery.

We understand your whole team is under pressure to deliver large projects. There is a lot at stake. By understanding your objectives and asking the right questions at the start we ensure that problems are pulled up and rectified before we begin.

This eliminates the risk of fabrication issues, on site dramas, installation issues and project time line blowouts.

We execute integrated engineering solutions resulting in efficiencies for projects and adding value for our clients.

Our project focus and sense of urgency coupled with detailed planning and world class fabrication has facilitated increases in efficiencies and consistently delivered lower costs for our clients.

Allspec Engineering has successfully completed the following list for Mining Companies accross Western Australia:

Primary and Secondary Crushing Spares

- Rom Beams

- Rom inserts

- Bin Liners

- Grizzly Spares

- Apron Feeder Structures

- Grizzly Cassettes

- Crusher Feed Chutes

- Transport Frames

Rotable Chutes Dry

Plant & Wet Plant

- Head Chutes

- Transfer Chutes

- Impact Baffles

- Trommel Chutes

- Screen Oversize Hoods

- Hoppers

- Impact Boxes

- Rubber Lined Boxes

- HPGR Chute

- Cyclone Clusters / Launders

- Transport Frames

Rotable Process Piping

- Process Water / Lube Spools

- Rubber Lined Spools / 3D Bends

- Ceramic Lined Spools / 3D Bends

- Polyurethane Lined

- HDPE Spools

Wear Liner Packages

- Detailing

- Liner Change Management

- Quench & Tempered Liners

- Welded Overlay Plate Liners

- Cast (Nihard) Liners Packages

- Billets & Rock Ledges

- Ceramic Liners

- Fabricated Lining Packages

- Inserts

- Packaged to suit efficient install (packaged per liner layout)

Reclaiming & Train

Load Out Spares

- Bogie wheels

- Reclaimer Bucket Wheels

- Reclaimer Buckets

- Ring Chutes

- Spill Faces

- TLO Bin Liners

- TLO Chutes – Fixed, Swing, Trim & Clamshell

- Transport Frames

Brown Field Project Supply

- New Buildings

- GTU Towers

- Counterweights

- New Process Hoppers

- Stockpile Vault Hoppers

- Vault Liners

- Transfer Chute replacements

- Chute Upgrades

- New Process Piping Supply

- Conveyor trusses

- Conveyor Walkways

- Grating and Handrails

- Pipe Bridges

- Tanks

- Non-Process Infrastructure

Non-Process Infrastructure

- MEM Workshops

- Heavy Vehicle Wash Bays

- Light Vehicle Wash Bays

- Sumps and Cast in Steelwork

- Diesel Storage Facilities

- Diesel Piping

- Safety Devices

- Barricading Pods

- Bollards

- ANFO Storage Facilities

- Storage Sheds

Grizzly Casette Spares and Refurbs

Primary Crusher Feed Chute

Rotable Ceramic Lined Impact Baffle

Reclaiming Sares Ring Chute

Train Load Out Spares and Refurb

Grizzly Casette Spares and Refurbs

Primary Crusher Feed Chute

Rotable Ceramic Lined Impact Baffle

Reclaiming Sares Ring Chute

Train Load Out Spares and Refurb

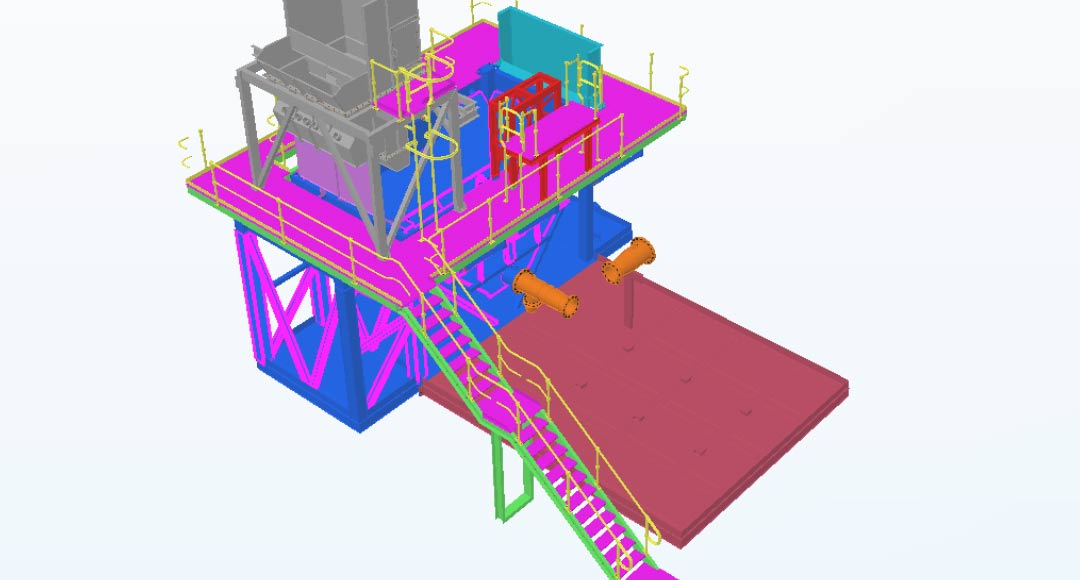

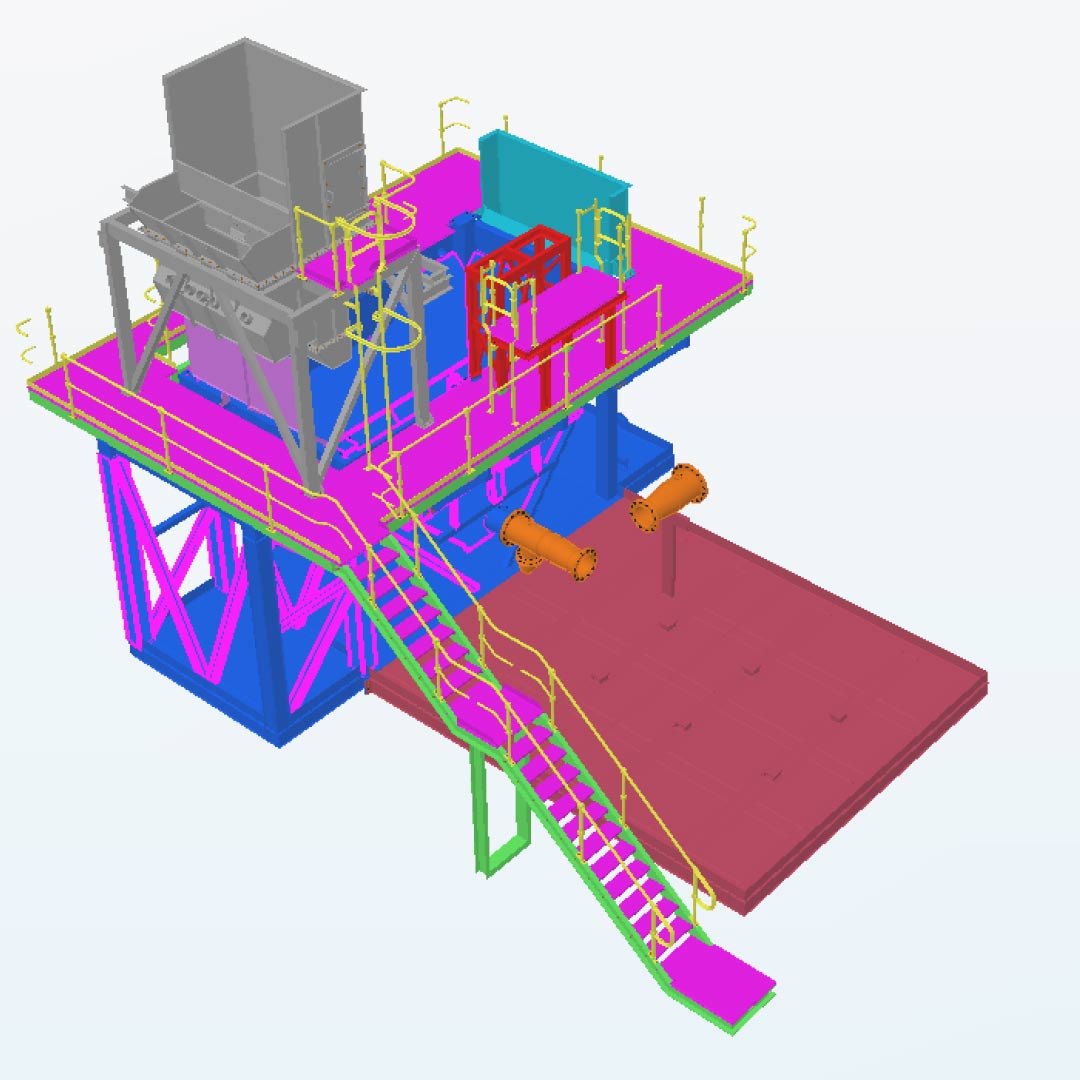

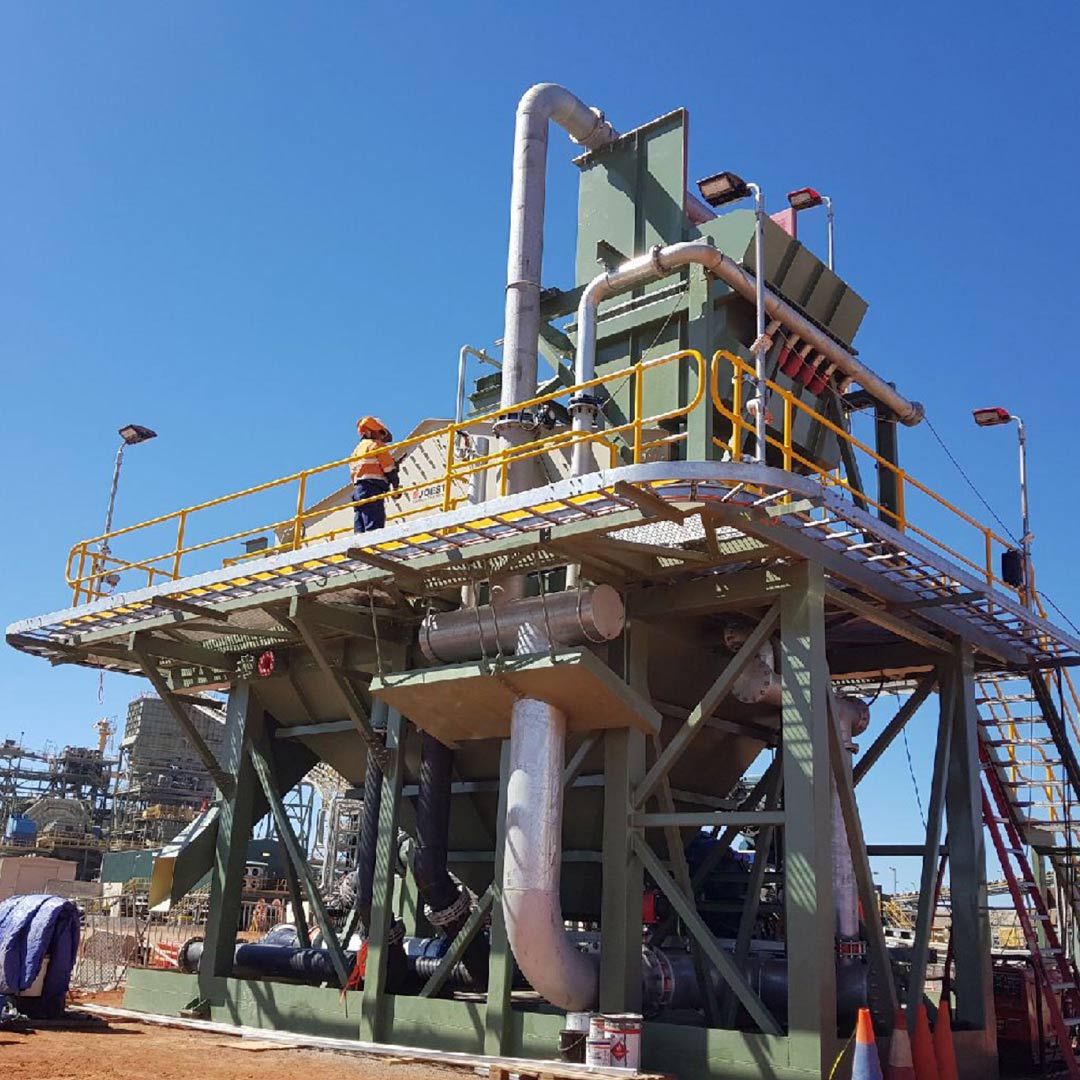

Case Study

Turn Key Project Management: Gold Mine Repulping Hopper

Completed on a very tight schedule for a critical shutdown.

As a result, our client can operate the fines repulper during a shutdown to maintain throughput while maintaining other parts of the fixed plant.

Allspec Engineering coordinated the shop detailing, fabrication, NDT, trial assembly, surface treatment, rubber lining and delivery to site.

Our dedicated Project Managers and workshop team worked 13 day fortnights and a project specific night shift to achieve this goal. In our peak we had 60 tradesman dedicated to this project.

All structural steelwork and chute fabrication was completed to AS/NZS1554.1 and all piping was completed to AS4041 under control of our in house AS1796 + AS2214 welding supervisor.

Trial assembly was completed using our qualified riggers and crane operators at our Henderson facility. The OEM screen and pump was also trial fitted to ensure design was sound.

Majority of the rigging gear was installed on the finished steel work by our riggers prior to dispatch to reduce working at height risks to personnel unloading the trailers on site.

A total of ten semi trailers were dispatched for the successful delivery of this project. All trailers were on time and in order of construct-ability sequence to ensure timely unloading and streamlined installation.

3D modelling to 2D detailed shop drawings

From model to fabrication in 1 week

Rubber lined, expediting and rigging gear installed

Delivered in full and on time

3D modelling to 2D detailed shop drawings

From model to fabrication in 1 week

Rubber lined, expediting and rigging gear installed

Delivered in full and on time

Your Project Our Focus

Results Driven Fabrication Services

Your Project Our Focus

Results Driven Fabrication Services

Download Capabilities Statement:

Download Capabilities Statement: