Precision Fabrication

For Mine Construction

We help Mine Construction Companies deliver successful infrastructure projects by focusing on world class fabrication and project clarity, right from the start.

Precision Fabrication

For Mine Construction

We help Mine Construction Companies deliver successful infrastructure projects by focusing on world class fabrication and project clarity, right from the start.

Download Capabilities Statement:

Download Capabilities Statement:

Our vertically integrated supply chain ensures complete control and transparency throughout the entire project, from detailing through to site delivery.

Delays Cost!

No one wants to see messy construction projects leading to further project delays that could be easily solved with clear communication.

Also, fabricators being late on supply is one thing, but poor engineering strength and longevity due to sub standard fabrication can hurt the profitability of your mine into the future.

Gaining project clarity right from the start is the only way to consistantly deliver successful installations that fit perfectly and go the distance for our clients.

We achieve this by:

- Detailing Collaboration for Complete Clarity

- Intelligent Drawings, Project Planning, & Procurement

- Technology and Process Driven Fabrication

- Integrated Logistics & Installation

- Full Spectrum Quality Control

Allspec Engineering has successfully completed the following list for Mining Companies, Construction Companies and Contract Crushing Companies across Western Australia:

Fixed Plant Structural Steelwork

-

Stick steel

-

Overland Conveyor Modules

-

Conveyor Trusses

-

Conveyor Trestles

-

Screen Surge Bin Structures

-

Crushing Surge Bin Structures

-

Tripper Assemblies

-

Screenhouse Shuttle Assemblies

-

Belt Feeder Frames

-

Apron Feeder Frames

Fixed Plant Platework

-

Cast in Wear Packages

-

Head Chutes

-

Transfer Chutes

-

Impact Baffles

-

Trommel Chutes

-

Sample Station Chutes

-

Screen Oversize Hoods

-

Hoppers

-

Impact Boxes

-

Rubber Lined Boxes

-

Cyclone Clusters / Launders

-

Storage Tank Strakes

-

Fabricated Tanks – Storage & mixing

-

Specialty Transport

-

Transport Frames

Non-Process Infrastructure

-

MEM Workshops

-

Heavy Vehicle Wash Bays

-

Light Vehicle Wash Bays

-

Sumps and Cast in Steelwork

-

Diesel Storage Facilities

-

Diesel Piping

-

Safety Devices

-

Barricading Pods

-

Bollards

-

ANFO storage Facilities

-

Storage Sheds

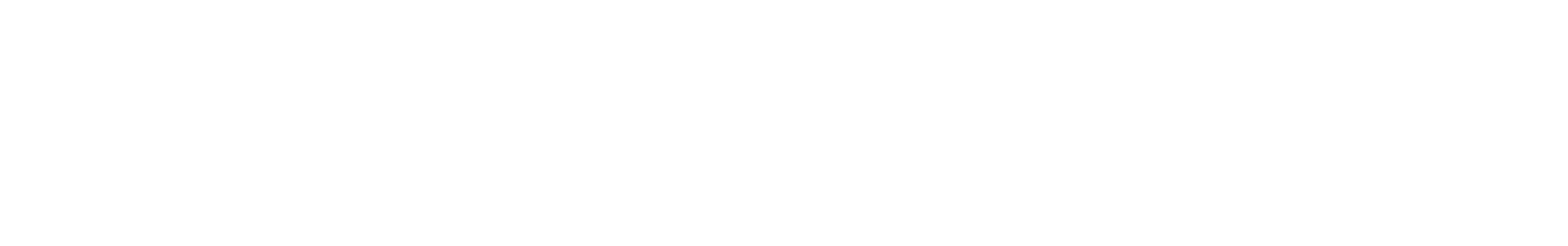

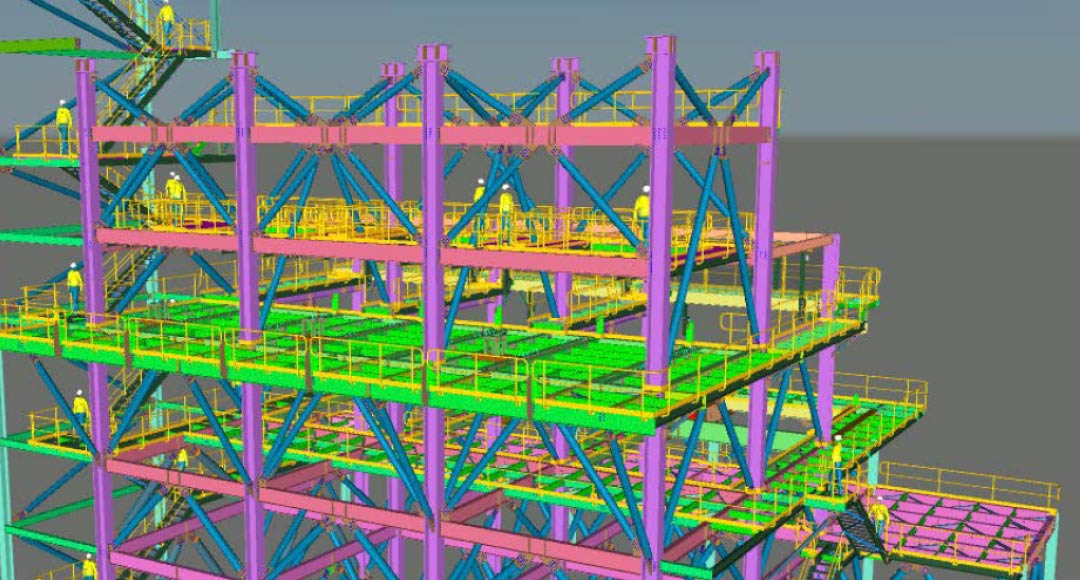

240T Screen Surge Bin

Lower Discharge Section

Main Toblerone Section – One of four supplied

285T Screening Structure to accept above Surge Bin

Cradle of Stick Steel

240T Screen Surge Bin

Lower Discharge Section

Main Toblerone Section – One of four supplied

285T Screening Structure to accept above Surge Bin

Cradle of Stick Steel

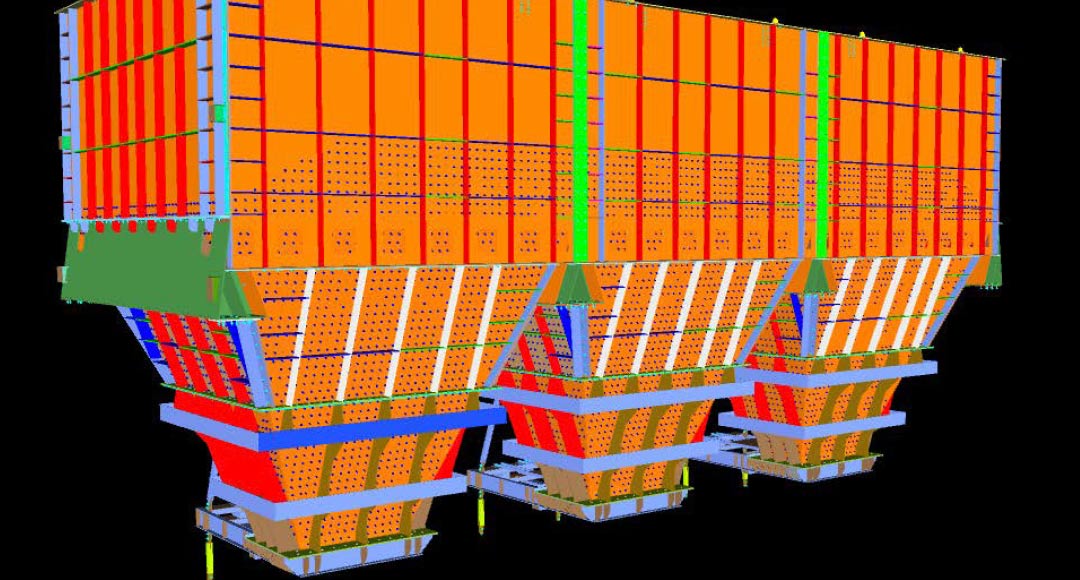

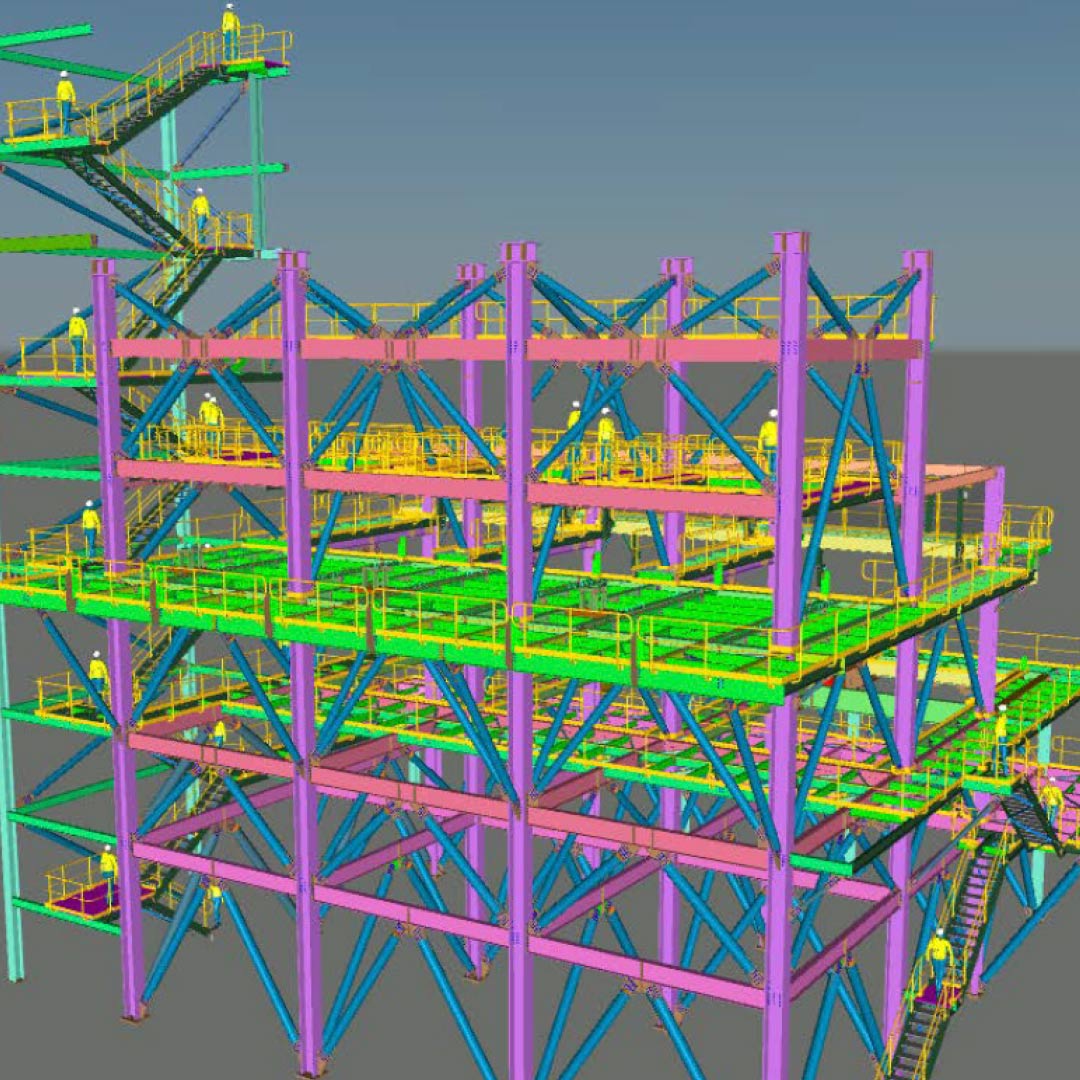

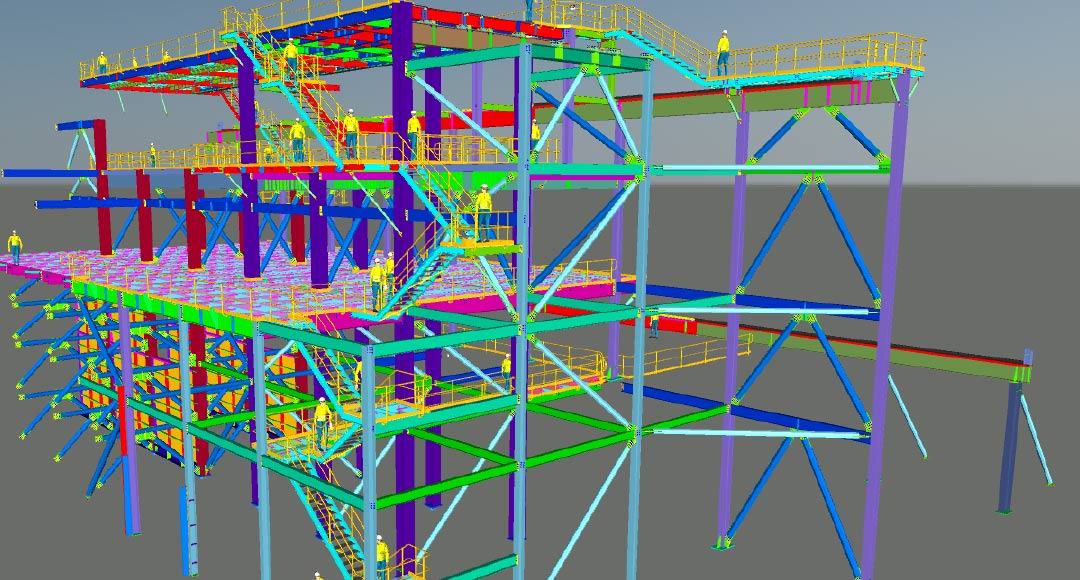

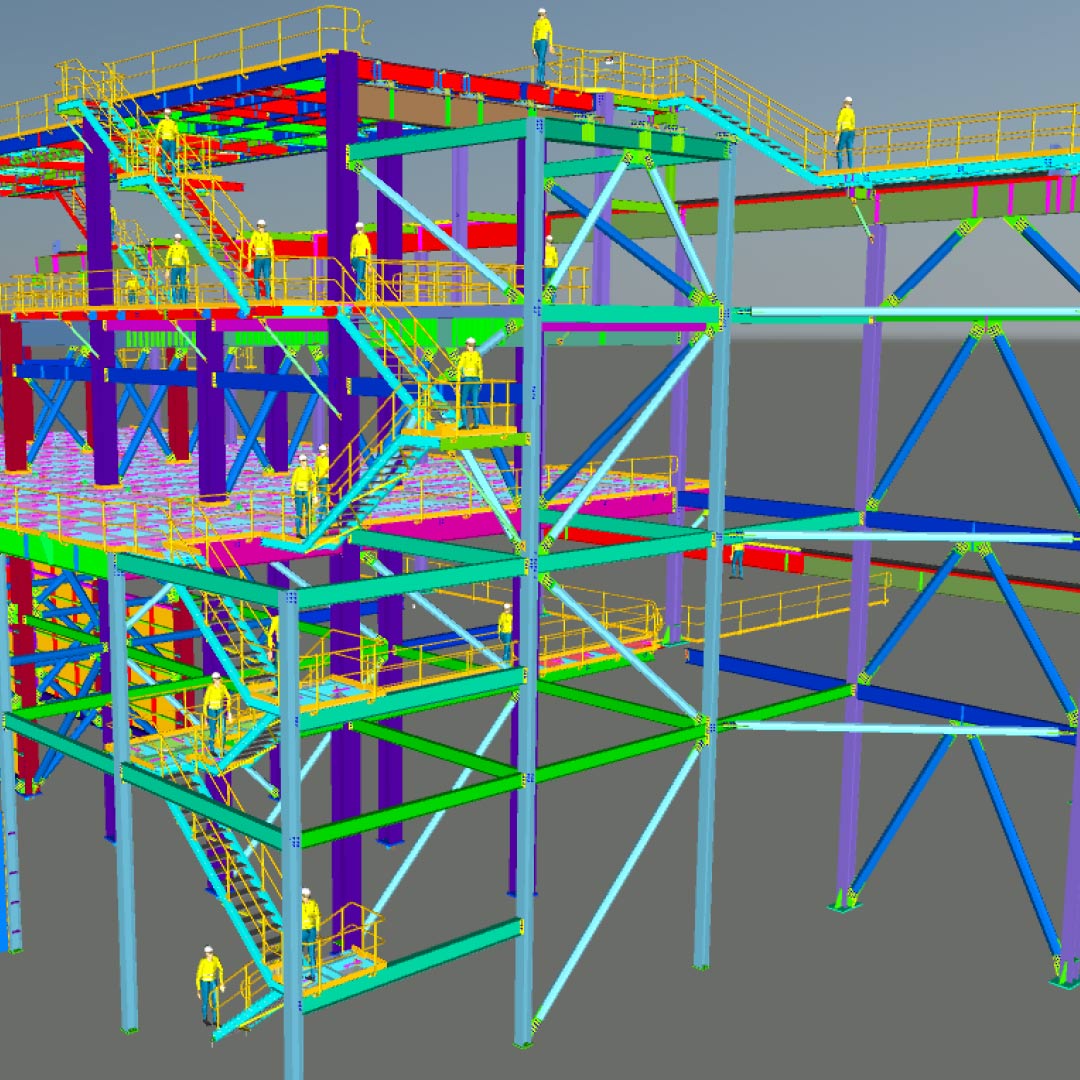

Case Study

Turn Key Project Management: Wodgina Crusher Structure

350T delivered in 8 weeks

While structural steel is not the most complex of fabrication works, it does rely on economy of scale, capacity and efficiency.

Asking our client the right questions at the start of the project enabled efficient and expedient project management to get the desired outcome. With such a tight timeline and specific quality requirements, open communication between our managers and the client made for a smooth operation.

Our client needed this package delivered in-line with their specific construction methodology. Working with our client, Allspec were able to prioritize and execute to spec.

We understand the importance of efficiency. Allspec was able to achieve notable cost savings during the fabrication process and hitting the delivery target created an easier than expected installation on site. This validated the clients decision to steer away from overseas fabrication.

Even the delivery details where prioritized with cradles packed with nothing but Jarrah Hardwood gluts with carpet to protect the paint.

Another successful project delivered in full and

on time.

A model shot of the 350T Crusher Structure

Hungry Boards – 8T each

18M Long Shuttle Rails for Crusher Structure

Delivered to site in full and on time

A model shot of the 350T Crusher Structure

Hungry Boards – 8T each

18M Long Shuttle Rails for Crusher Structure

Delivered to site in full and on time

Your Project Our Focus

Results Driven Fabrication Services

Your Project Our Focus

Results Driven Fabrication Services

Download Capabilities Statement:

Download Capabilities Statement: