Allspec Engineering Proof of Performance

Allspec

Engineering

Proof of

Performance

We execute large scale fabrication using proven processes that deliver quality components time and time again.

DIFOT – Delivered In Full and On Time

Case Study

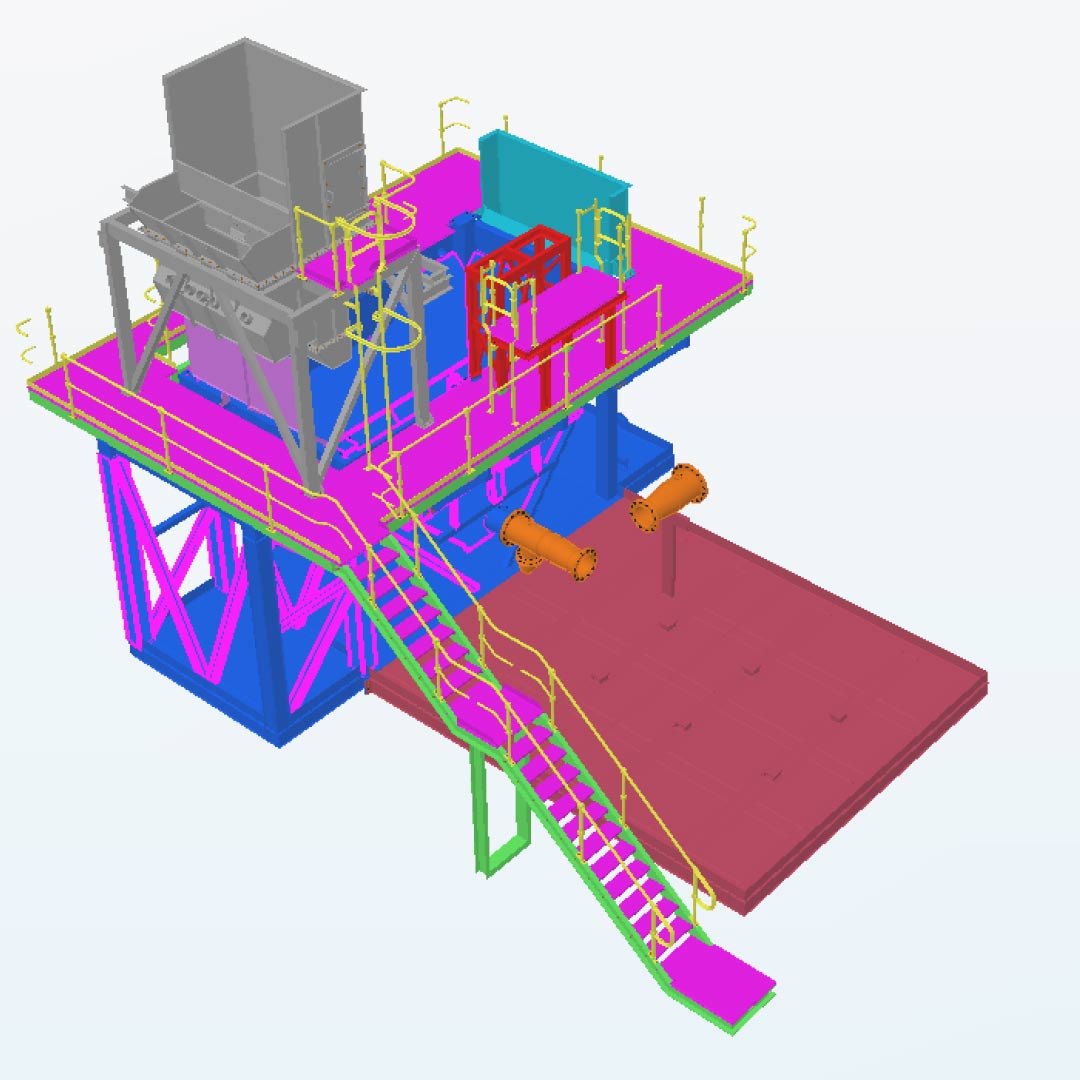

Turn Key Project Management: Gold Mine Repulping Hopper

Completed on a very tight schedule for a critical shutdown.

As a result, our client can operate the fines repulper during a shutdown to maintain throughput while maintaining other parts of the fixed plant.

Allspec Engineering coordinated the shop detailing, fabrication, NDT, trial assembly, surface treatment, rubber lining and delivery to site.

Our dedicated Project Managers and workshop team worked 13 day fortnights and a project specific night shift to achieve this goal. In our peak we had 60 tradesman dedicated to this project.

All structural steelwork and chute fabrication was completed to AS/NZS1554.1 and all piping was completed to AS4041 under control of our in house AS1796 + AS2214 welding supervisor.

Trial assembly was completed using our qualified riggers and crane operators at our Henderson facility. The OEM screen and pump was also trial fitted to ensure design was sound.

Majority of the rigging gear was installed on the finished steel work by our riggers prior to dispatch to reduce working at height risks to personnel unloading the trailers on site.

A total of ten semi trailers were dispatched for the successful delivery of this project. All trailers were on time and in order of construct-ability sequence to ensure timely unloading and streamlined installation.

3D modelling to 2D detailed shop drawings

From model to fabrication in 1 week

Rubber lined, expediting and rigging gear installed

Delivered in full and on time

3D modelling to 2D detailed shop drawings

From model to fabrication in 1 week

Rubber lined, expediting and rigging gear installed

Delivered in full and on time

Case Study

66T South Flank Tie In Trusses

Completed on schedule and on budget delivering a critical section of mine infrastructure for our client.

Due to the size and width of the trusses, TQ’s were required to determine best slice locations for all the main chord sections and chequer plate flooring.

Clearly written technical queries sent to our client at the very start of the process saved a lot of time and avoided costly delays.

Choosing the correct welding processes, positions and welding pattern reduced distortion of the floor and square bar joints, reducing the need for post weld straightening. This made the process quicker and removed any unnecessary labour.

Specialist lifting gear was required in order to protect the lifting lugs from side loading. This all had to be communicated, witnessed and managed down at our sub-contractor’s paint facility.

Fabricated in accordance with AS/NZS 5131 and welded in accordance with AS/NZS 1554.1 SP.

Fully assembled prior to dispatch.

By understanding the end user’s needs we helped achieve an economical and time efficient outcome while delivering the strength and durability required by the engineers. We had a happy client and happy end user.

3D modelling to 2D detailed shop drawings

Loadout to surface treatment

Trial fit handrails, NDT and final inspection

Painted in four different paint systems as per client specifications

3D modelling to 2D detailed shop drawings

Loadout to surface treatment

Trial fit handrails, NDT and final inspection

Painted in four different paint systems as per client specifications

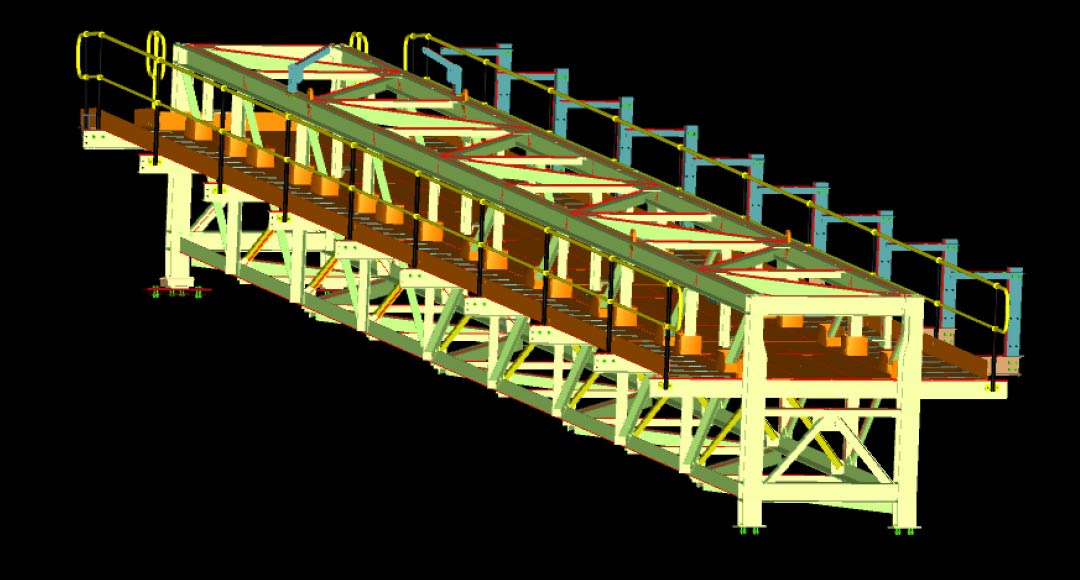

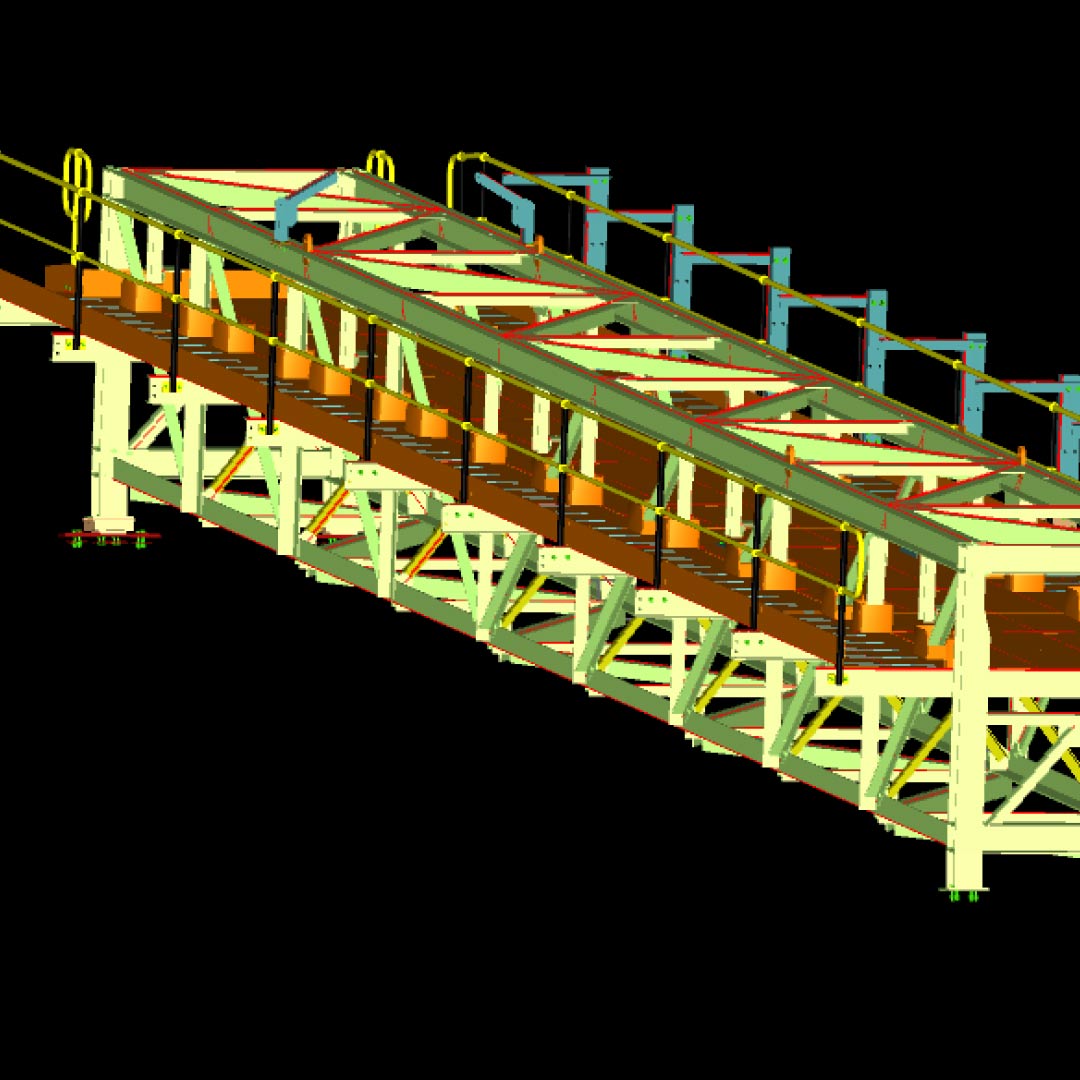

Case Study

Yandi Dry Plant Upgraded Belt Feeder

18T ASSEMBLED

18.5m LONG

4.3M WIDE

Belt Feeders need to be straight! This frame was built in four different sections due to the design, changing heights and widths of the feeder. Only the tie in points were positionally welded. Allspec completed the precision fabrication, pre and post machining survey and mechanical fitout.

Thinking of our clients needs, we queried the need for bolt on lifting lugs for site unloading and install. These were caught before surface treatment had started, keeping the cost to a minimum.

The upgraded belt feeder was fully assembled prior to dispatch to reduce any onsite confusion and time delays. The project went very smoothly with a happy client and happy end user.

By understanding the end user’s needs we were able to suggest and implement improvements that led to substantial cost savings and a shorter delivery time for our client.

Precision fabrication on onsite machining for drive pulley

Mechanical assembly and belt splice completed

Reducing site hours by installing idlers and frames offsite

Delivered in full and on time

3D modelling to 2D detailed shop drawings

From model to fabrication in 1 week

Rubber lined, expediting and rigging gear installed

Delivered in full and on time

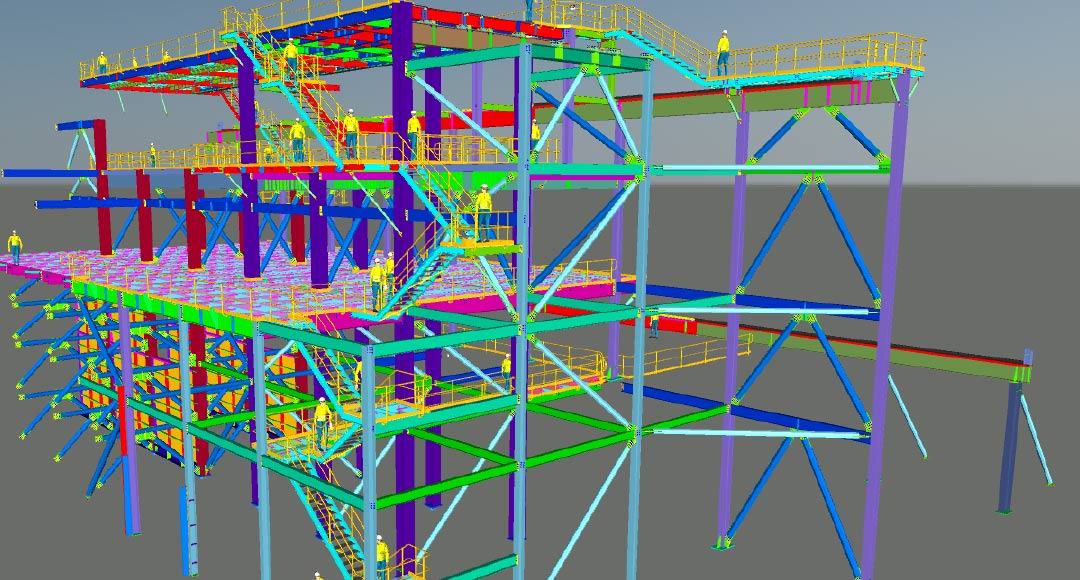

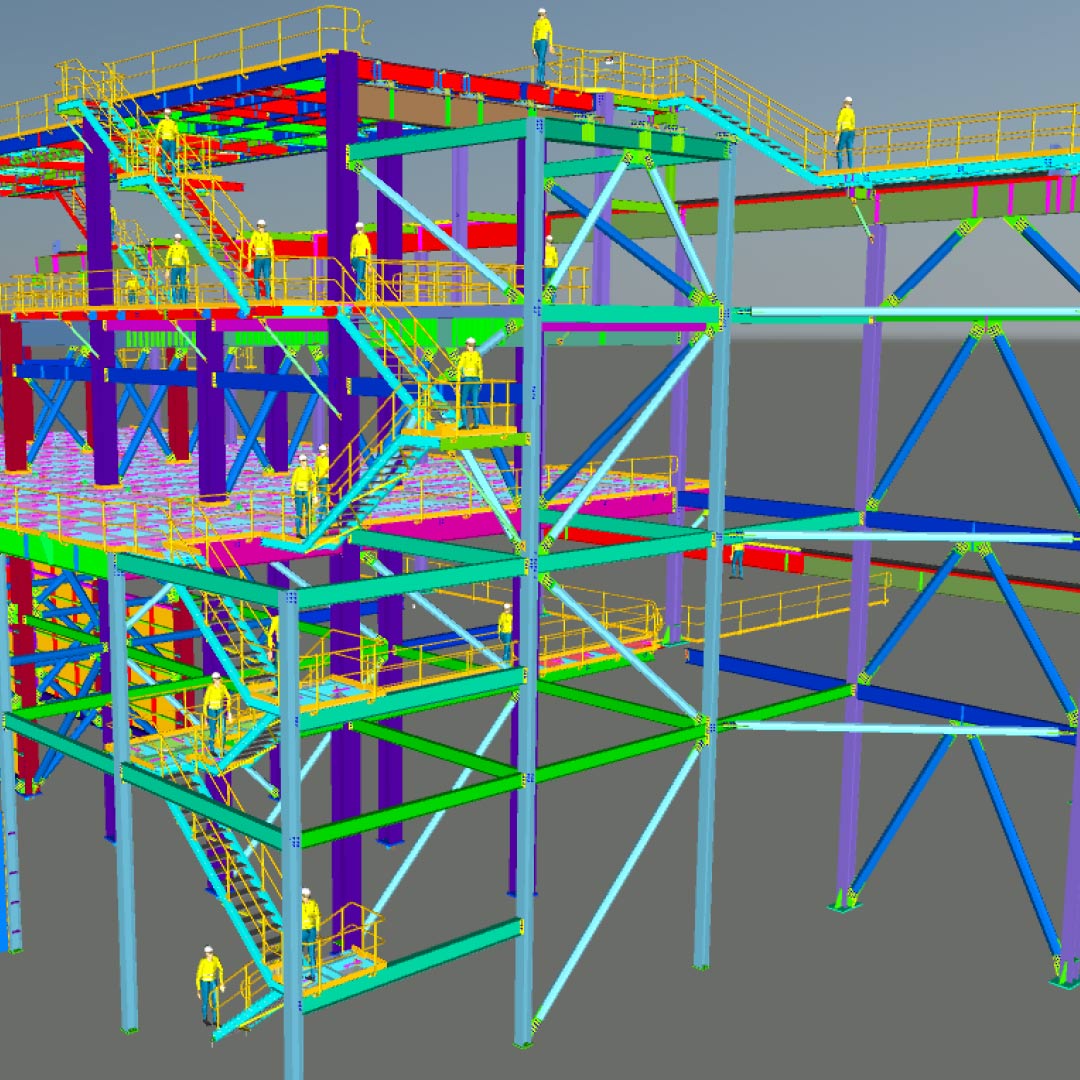

Case Study

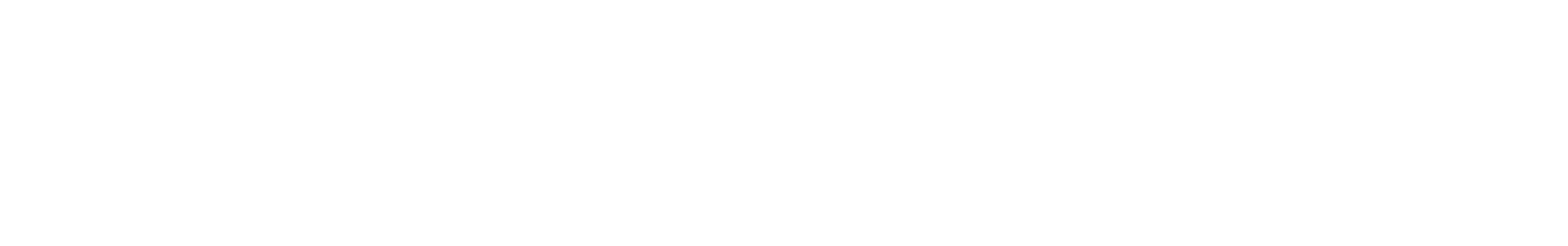

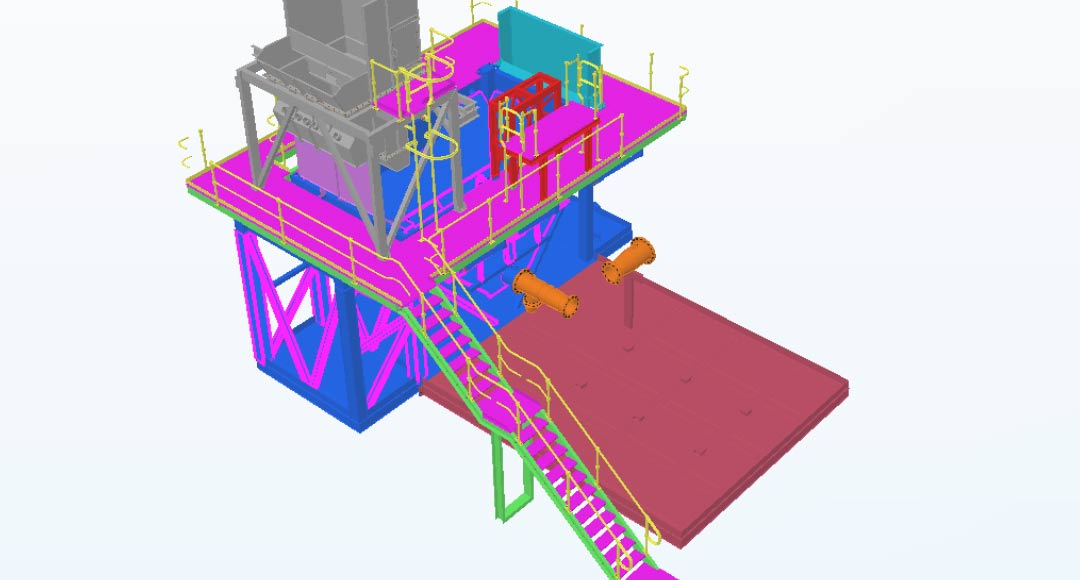

Turn Key Project Management: Wodgina Crusher Structure

350T delivered in 8 weeks

While structural steel is not the most complex of fabrication works, it does rely on economy of scale, capacity and efficiency.

Asking our client the right questions at the start of the project enabled efficient and expedient project management to get the desired outcome. With such a tight timeline and specific quality requirements, open communication between our managers and the client made for a smooth operation.

Our client needed this package delivered in-line with their specific construction methodology. Working with our client, Allspec were able to prioritize and execute to spec.

We understand the importance of efficiency. Allspec was able to achieve notable cost savings during the fabrication process and hitting the delivery target created an easier than expected installation on site. This validated the clients decision to steer away from overseas fabrication.

Even the delivery details where prioritized with cradles packed with nothing but Jarrah Hardwood gluts with carpet to protect the paint.

Another successful project delivered in full and

on time.

A model shot of the 350T Crusher Structure

Hungry Boards – 8T each

18M Long Shuttle Rails for Crusher Structure

Delivered to site in full and on time

A model shot of the 350T Crusher Structure

Hungry Boards – 8T each

18M Long Shuttle Rails for Crusher Structure

Delivered to site in full and on time

Your Project Our Focus

Results Driven Fabrication Services

Your Project Our Focus

Results Driven Fabrication Services

Download Capabilities Statement:

Download Capabilities Statement: